Waterproof work boots are one of those rare things for which technology has offered gains in quality while driving down cost. The result is a shoe that is not limited in use. Waterproof shoes can be found anywhere from the most rugged safety boots for industrial conditions to elegant dress oxfords and boots worn to work in the corporate world.

Today waterproof work boots are less than half the price, more stylish and easily more effective than they were only a few years ago, primarily because of the expiration of the Gore-Tex patent. There has also been improved technology in working with leathers. Both of these developments have allowed for more competitive waterproof membrane materials, lower prices, and more demand, which have resulted in many more affordable, waterproof shoes.

Quite simply, these advantages can be seen in the two different approaches manufacturers use to create their waterproof safety shoes: The waterproof membrane “bootie” and the seam-sealed construction are the two methods for making waterproof shoes.

The waterproof membrane “bootie” (it looks like a “baby’s bootie” sock) is made of Gore-Tex inspired, waterproof membrane material, which is now made by many manufacturers, and then formed into the “bootie”, protective liner and placed between the leather and the linings of the shoe to give the foot a breathable, waterproof environment to work. Because the material has nine billion pores per square inch and each pore is 1/20,000 the size of a water droplet, water cannot get through the membrane, but water vapor, like perspiration, can easily escape. This fabric has a cellophane-like consistency and is laminated to the lining materials and then sewn into the lining “bootie”. The seams of the bootie are sealed with specially made waterproof membrane tape, creating a water tight barrier which is assuredly the best waterproof system for footwear available.

While the Gore-Tex inspired “bootie” (or membrane) is the best waterproof system for footwear, seam-sealed waterproof construction is another inexpensive option, that it is used less often than it used to be because membrane waterproof footwear is so much less expensive today. This construction is made by “seam sealing” all the needle holes of the stitches in the leather upper of the boot with a thick latex material. Then typically, the sole is put on the leather upper in a liquid state so it bonds directly to the leather creating a water tight seal.

The disadvantage of the seam-sealed waterproof process is the leather has to be maintained. That’s because organic, porous leather is impossible to waterproof; unless the leather is given a urethane coating or “stuffed” with silicones and oils. But this treatment is only temporary because when leather is exposed to the environment, these materials in the leather begin to dry out and the leather eventually loses its waterproof nature. That’s why manual oiling the leather on a regular basis is necessary to keep water resistance in place. There are many waterproofing materials for full grain leathers (not suedes), like mink oil, silicones, bees wax materials, but maybe the simplest and most economical is baby oil. It works and keeps boot leather soft and supple, but you have to consistently apply the treatment when you notice the leather surface drying or dulling. If your boots are made with a suede or Nu-buck leather, silicone liquid or spray is the preferred waterproofing agent.

The waterproof membrane waterproofing system is clearly the best and most effective option, but if the outer leather is not well maintained, the leather will dry out, harden, and crack over time and render itself useless; despite the stellar technology housed within.

It must also be said, that any leather shoe, used in any way, would require similar maintenance. And due to the amount of water and/or chemicals in certain environments, the oils on a leather work boot may be depleted of its natural water resistance more rapidly than in less invasive situations.

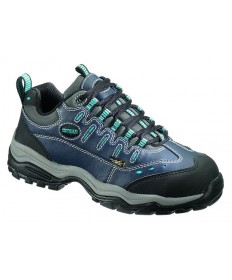

Well-made, waterproof work boots are offered by most all major companies and brands such as Hy-Test, Timberland, and Wolverine.

Read more about steel toe waterproof work boots in our next article.